Logistics

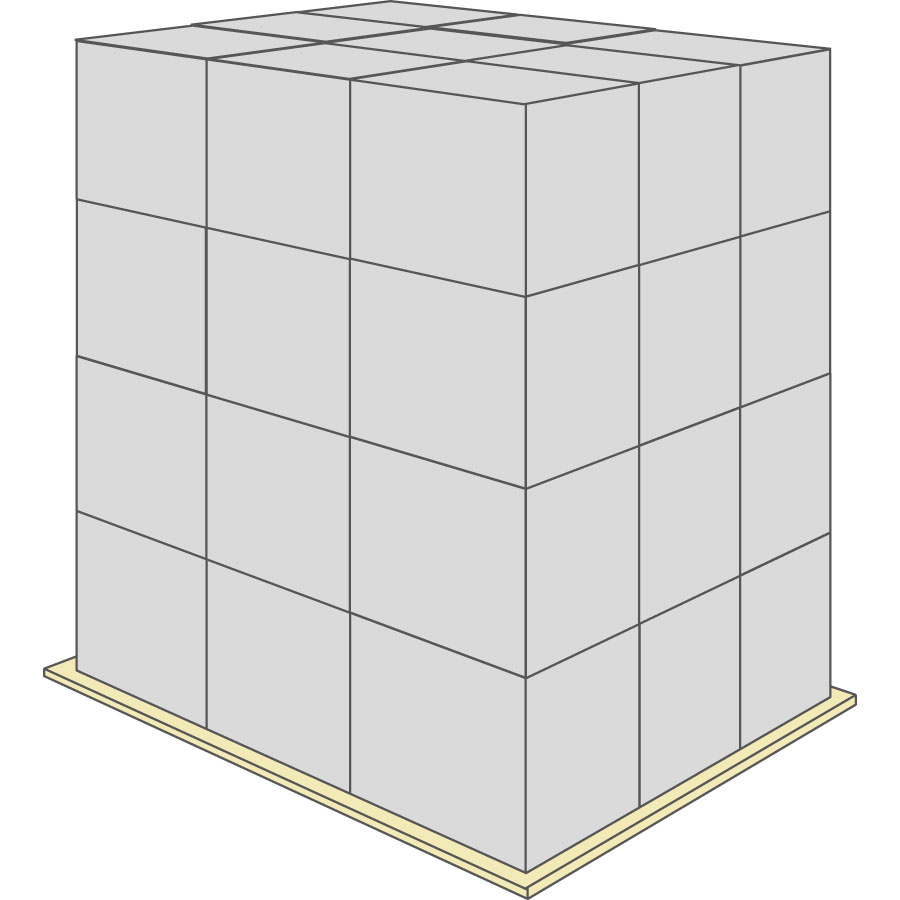

A perfectly well-structured cube is not always what we meet when dealing with wrapping of pallet loads.

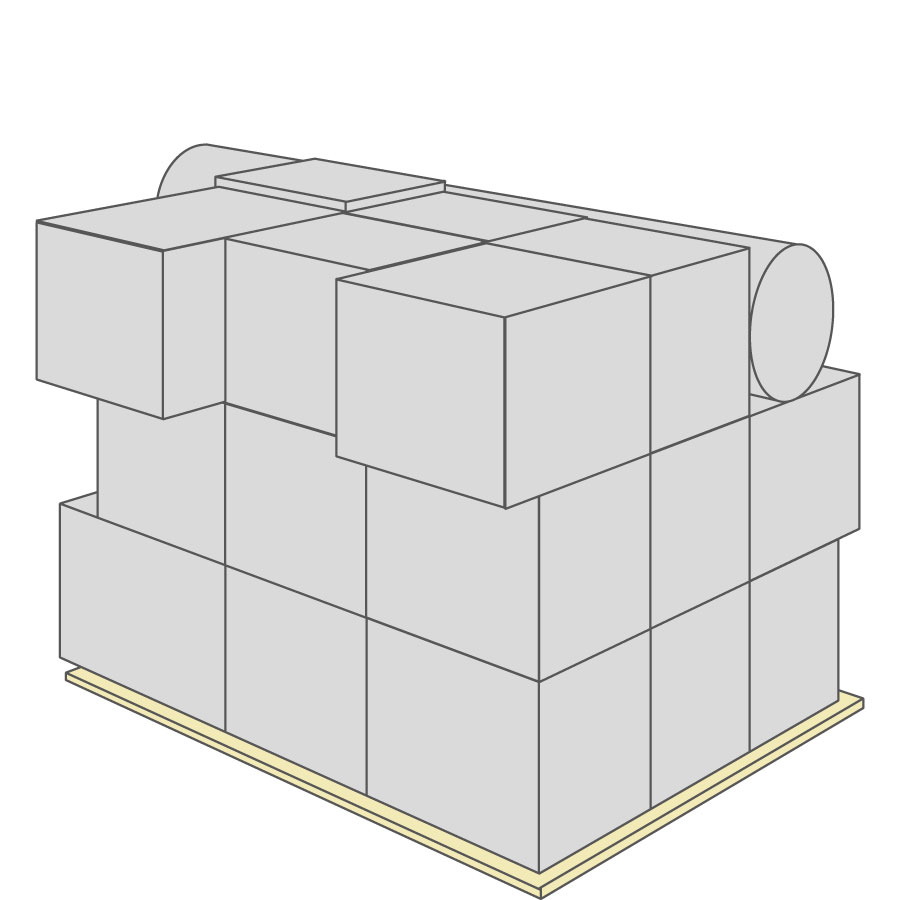

Especially in distribution centers pallets can vary greatly from one order to the other. At many distribution centers as well as many manufacturing facilities in general we meet pick and pack stations where operators are building pallets based on incoming orders.

The challenge at these facilities is finding the optimum wrapping solution which is able to adapt to the various applications and load structures.

Before

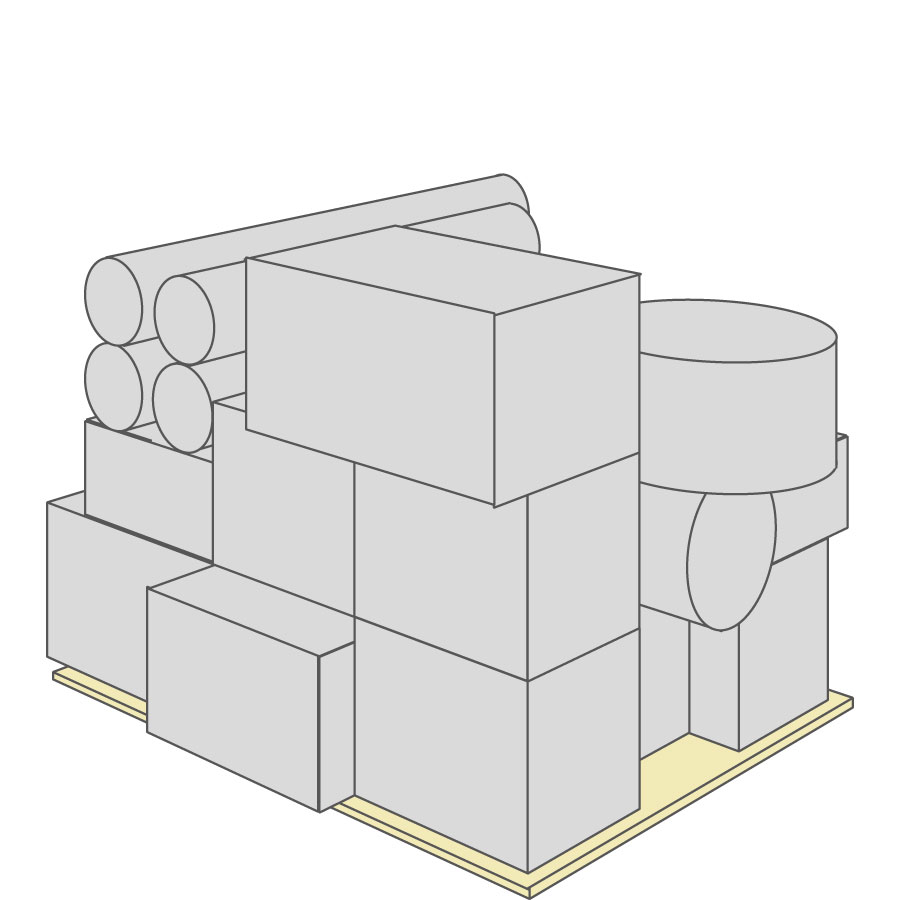

Irregular load shapes

Especially logistic pallet loads characterised by irregular load shapes and sizes require the perfect wrapping in order to withstand the stresses caused by handling, impacts and vibrations, be it on trucks, trains, ships or airplanes.

The solution for Trixie, the German trading company for pet products, was the Lachenmeier stretch hood solution.

After

Lachenmeier stretch hood is the solution...

No matter if tall, unstable, lightweight, heavy, column-stacked pallets or irregular pallet loads with many corners and sharp edges.

Adding to the complexity is that fact that logistic pallets often are having either overhang or especially underhang, where the complete surface of the pallet is not covered with products leaving a void space.

Knowing how to...

No matter if you need to wrap a perfectly normal cubed load with no protrusion, a slightly more irregular pallet load with only few protrusions and varying product shapes, or if you are dealing with the extreme irregular loads with many corners, possible sharp edges or soft corners, etc. you need to have a flexible wrapping which can perfectly adapt to the shape of the load.

At the same time, you need a machine which can apply the film in a way avoiding crushing or otherwise damaging the products.

Check out the Lachenmeier Stretch Hood solution.

High Speed Wrapping

Check out our flexible stretch hood wrapping machine Multi FleX1 for high speed wrapping.

Read more about the Multi FleX1 stretch hood