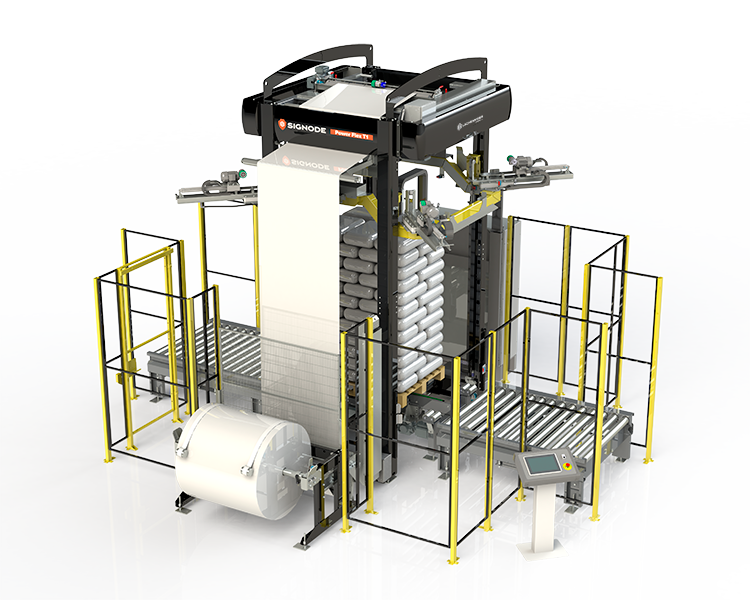

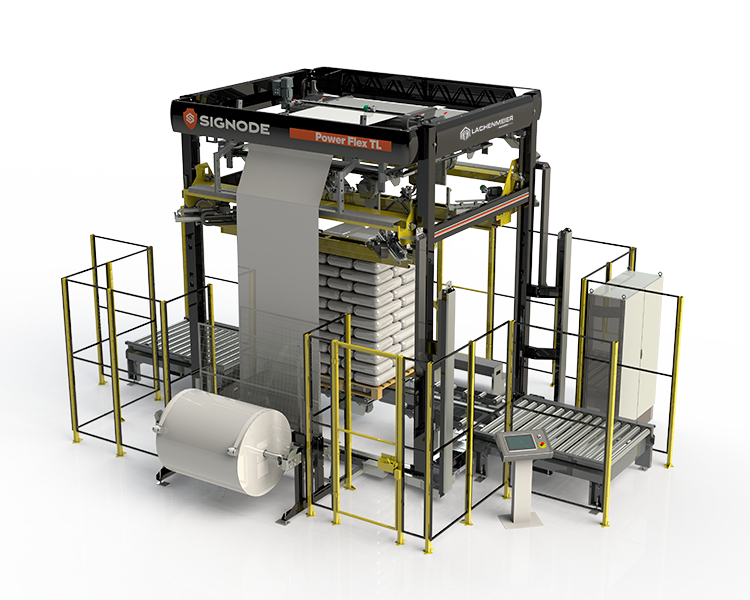

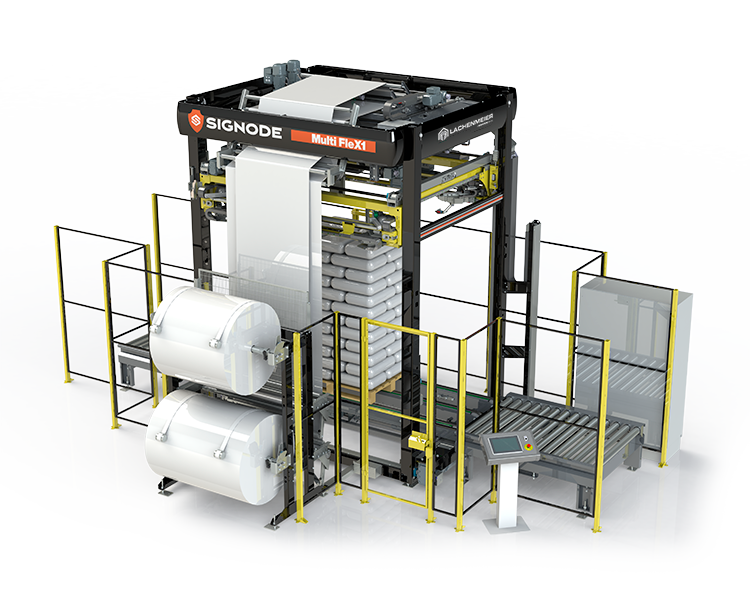

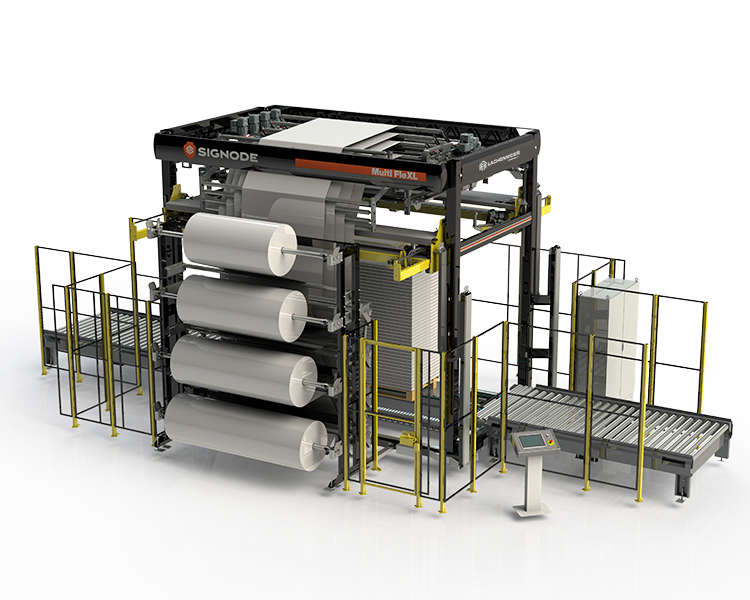

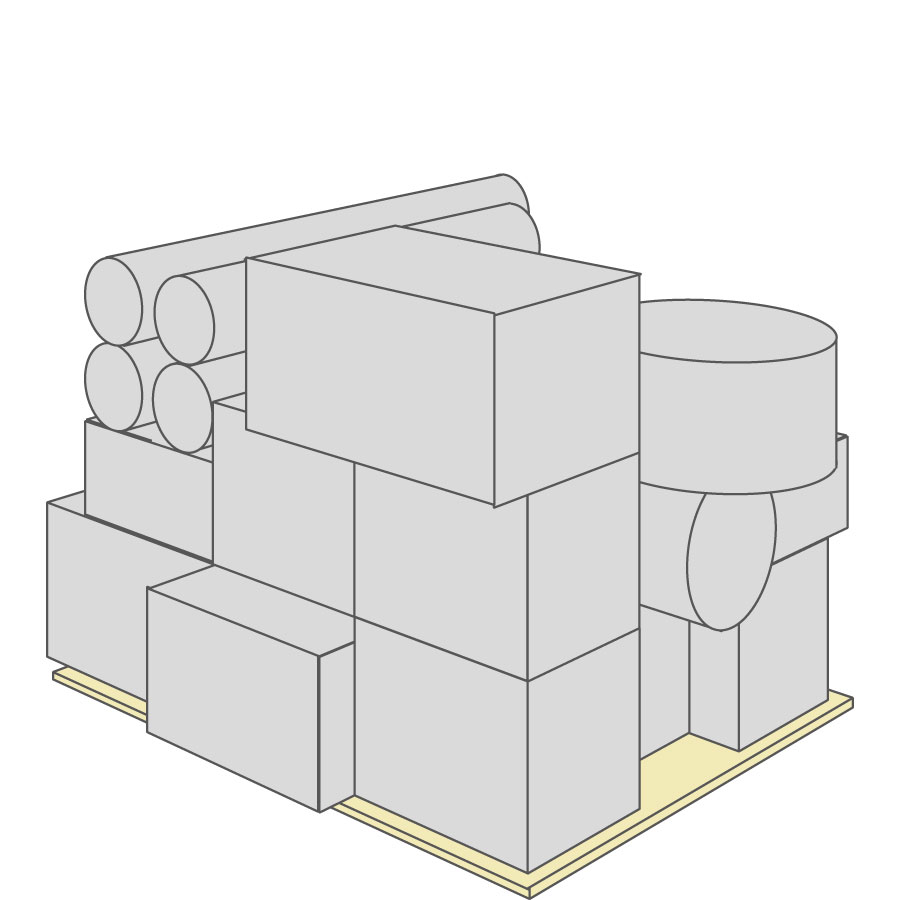

Load shapes and wrapping patterns

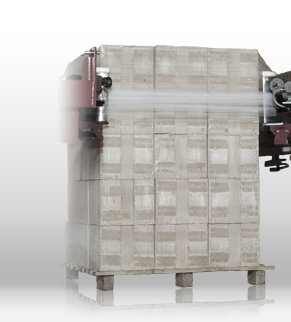

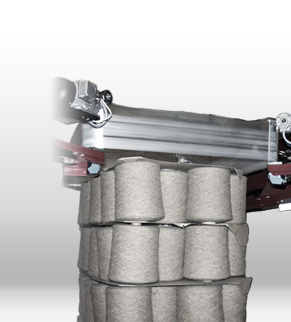

Signode stretch hood is not just a closed film bag being applied to a uniform load. We can apply film sleeves as well as short hoods, we can wrap with perforated film to avoid condensation as well as apply film reinforcement on the load where needed. At the same time stretch hood is also suitable for products with different shapes and sizes where traditional stretch wrap in particular tends to fall short, such as loads with irregular shapes, single layers, with sharp edges or protrusions as well as in-bound loads.

100% Waterproof Pallet Wrapping

Industries

Signode supplies end-of-line packaging machinery to various industries worldwide.

Read on to learn more about which packaging solutions we recommend for different industries, read case stories on some of our customers, who have chosen to rely on the Signode packaging technology – known on the market for more than 40 years – and see for yourself – pictures showing the wrapping result of the different wrapping technologies.

You name it - we wrap it ...!

Downloads

Please click below to view or download information regarding our different packaging machines.

Should you need further information, please contact us.

Contact us

Knowing how to wrap...

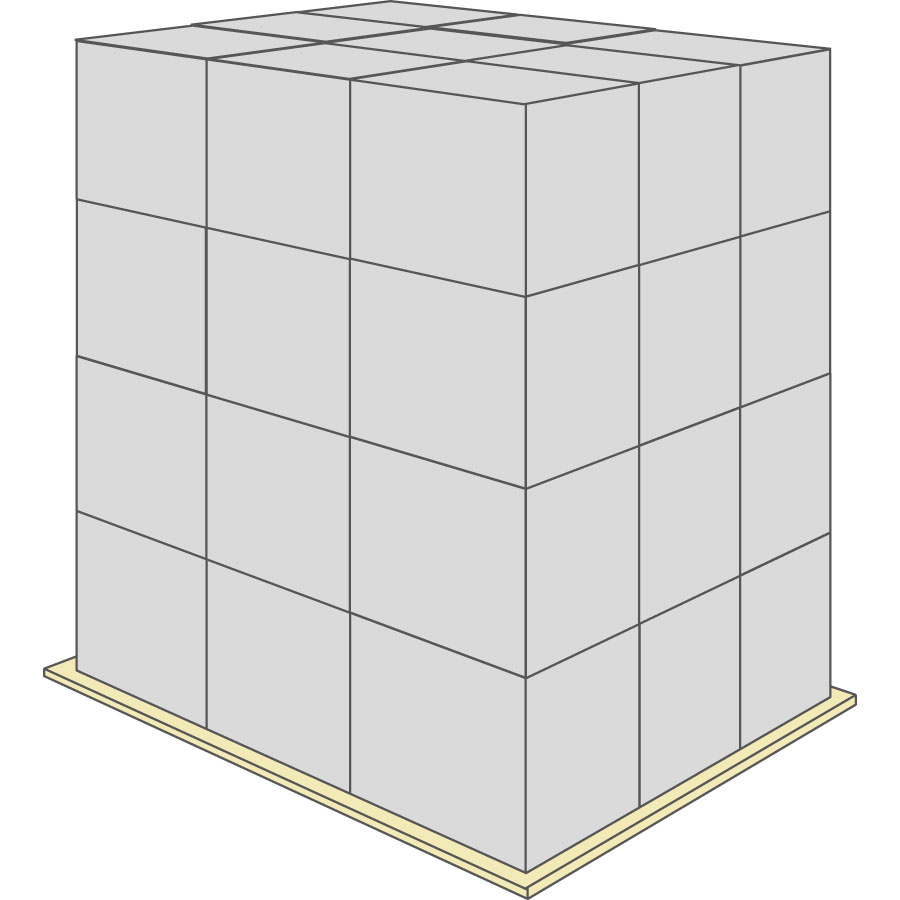

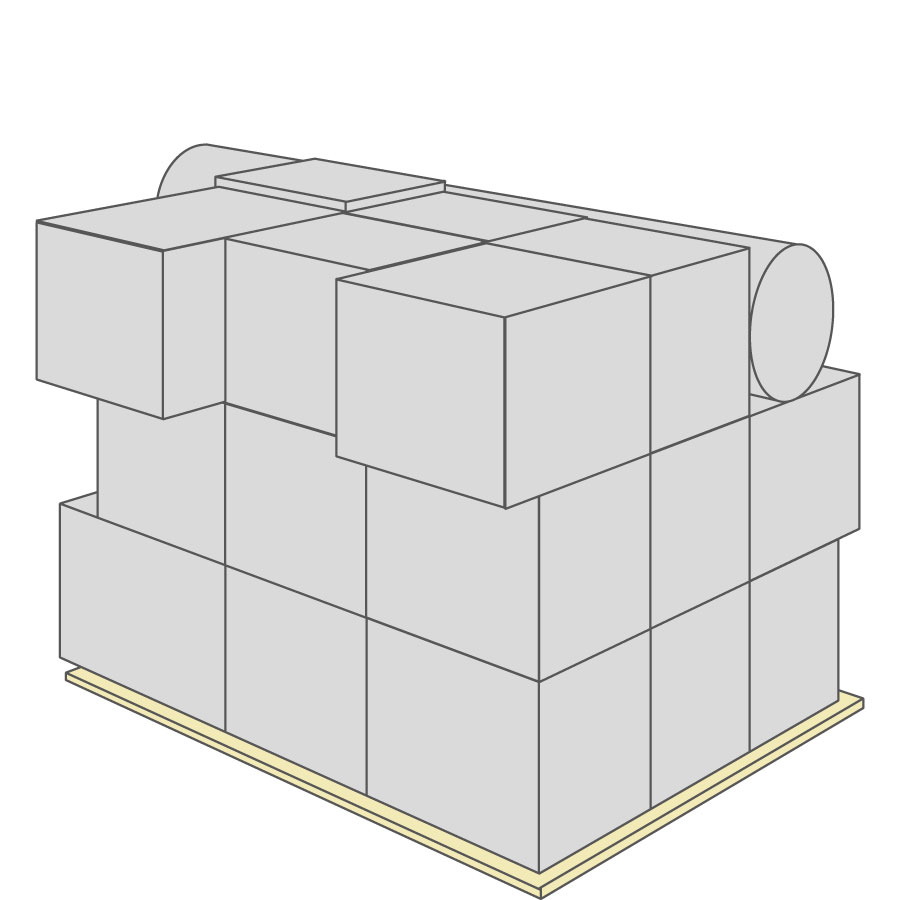

No matter if you need to wrap a perfectly normal cubed load with no protrusion, a slightly more irregular pallet load with only a few protrusions and varying product shapes, or if you are dealing with extremely irregular loads with many corners, possible sharp edges or soft corners, etc. you need to have a flexible wrapping solution which can perfectly adapt to the shape of the load.

At the same time, you need a machine which can apply the film without crushing or otherwise damaging the products.